The report or RPT text output file of SWMM 5 contains a table that lists the Surcharged Conduits during the simulation (Figure 1).

The 5 columns in the table are:

- Hours Both Ends Surcharged

- Hours Upstream End Surcharged

- Hours Downstream End Surcharged

- Hours Above Full Normal Flow

- Hours Capacity Limited

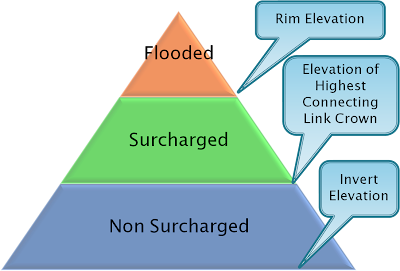

.the five columns are defined in Figure 2. Notice that if the midpoint of the link is full then the link and both end of the link are considered to be surcharged. If the midpoint is NOT full then the cross sectional area of the ends of the link determine wheter the ends of the link are considered surcharged. The end of a link can be considered surcharged based on either the depth at the midpoint or the cross sectional area at the end of the link.

Figure 1: The SWMM 5 Conduit Surcharge Table

Figure 2: The SWMM 5 Conduit Surcharge Table Definitions, the numbers in the 3rd column correspond to the columns in the Conduit Surcharge Table.